Compressed Air Engine

by Motor Development International, Luxembourg (MDI)

ADVANCED NEW DESIGN – AFFORDABLE – SCALABLE – EFFICIENT – ECOLOGICALLY SOUND

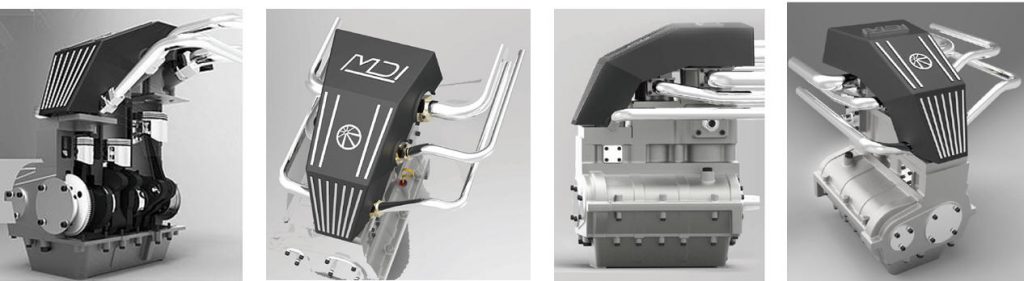

MDI Compressed Air Engine

ENGINE

- Simple & Efficient

- Based on the new MDI thermodynamic cycle.

- The primary energy is made outside the engine, and this gives much greater efficiency than the internal combustion engine.

- There is no internal combustion. That alone brings down the noise.

- The engine itself needs very little maintenance at all. Just 1 litre of vegetable oil every 25,000km.

- Efficient, clean external combustion, multi-fuel capable, enables competitive use of biomass fuels.

ENGINE EFFICIENCY

AIR ENGINE

Piston Engine

Well proven parts

Reversible

Becomes Compressor

430 cc – 7 kW 20 kg

1,000 cc – 60 kW 35 kg

2 COMPRESSED AIR ENGINES

MDI have created 2 compressed air engines which is the base of Automotive and Energy applications.

Small Engine

@ 1,500 rpm, 45 Nm, 430 c.c.

The engines can be grouped together (‘banked’) so, by way of example for electricity production, if 8 engines were banked with each engine providing 7 kW of electricity the total electricity provided would be 56 kW.

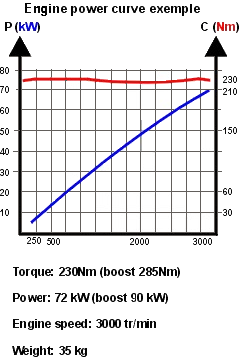

Larger 72 kW Engine

@ 3,000 rpm, 230 Nm, 1,000 c.c

The engines can be grouped together (‘banked’) so, by way of example for electricity production, if 8 of the larger engines banked together would provide over 500 kW of electricity.

MDI TECHNOLOGY

High Efficiency Compressed Air Engine

– Reversible as compressor

Modes of operation

– Air only

– Air + external combustion

Mono Energy – Mode 1 (available on all MDI vehicles)

The pre compressed air in the tanks is transferred to a chamber (called “active”) which provides “work” before being expanded in the cylinders to perform the stroke phase. There are no polluting emissions generated and the use of renewable energy in the air filling stations allows the production of a completely clean energy loop (compression – expansion).

Dual Energy Engine – Mode 2

The engine is the same as the Mode 1 engine, however a burner is added between the compressed air storage tank and the engine. The burner provides a continuous low temperature combustion increasing the volume of the intake air and therefore increases the freedom and independence of the system. The performance of the engine in terms of torque and power remain identical to Mode 1.

This external continuous combustion at a controlled temperature at around 600°C does not produce nitrogen oxides or sulphur dioxides and eliminates any discharge of unburnt hydrocarbons. Although using a fossil fuel, it is never the less a clean engine. Unlike the internal combustion engine, it is totally insensitive to the load (throttle position) and provides unparalleled consumption efficiency.

For example, on an AirPod, only 0.3l/100km (or 6.8g of CO2 per km) are needed to heat up the air coming from the tanks and double the range of the vehicle, and 0.5 l/100 km (or 11.4g of CO2 per km) are used to triple the range, up to nearly 450kms.

The operation in Mode 1 is always possible on the products equipped with dual energy Mode 2 engines. Mode 2 is used on all MDI vehicles.

SCALABLE